The packaging and labelling industry could see a raft of changes as we head into 2025, as regulations change, businesses continue to look for ways to reduce costs, and consumers demand greater transparency and sustainability.

In this blog, we’ll look at some of the potential legislation changes that lie ahead as well as examine how manufacturers can use automatic labelling to remain compliant.

What changes can we expect to labelling regulations in 2025?

- Medicines and Healthcare Products Regulatory Agency (MHRA) guidance

Under the Windsor Framework, medicines and medical devices require a ‘UK only’ label when distributed within the UK. Manufacturers holding marketing authorisations (MAHs) are expected to update their packaging by 1 January 2025 although a six-month transition period allows for temporary over-stickering until 30 June 2025. - CLP (Classification, Labelling and Packaging) Regulations

Changes to the Great Britain (GB) Mandatory Classification and Labelling (MCL) list, which governs the classification, labelling, and packaging of substances and mixtures, are due to come into effect on 2 September 2025. Businesses handling a number of substances, particularly those classified as carcinogenic, toxic or harmful to the environment will need to revise hazard labels, safety data sheets, and packaging to meet the updated classifications. - Not for EU labels

Plans to introduce mandatory ‘Not for EU’ labels across the entire UK were scrapped earlier this year, meaning while manufacturers selling goods in Northern Ireland must use ‘Not for EU labels, those selling only in Great Britain don’t have to. However, manufacturers should be aware that if there is deemed to be disruption, such as products being withdrawn from sale in the region, the government could yet decide to introduce a UK-wide labelling mandate. - Extended Producer Responsibility for Packaging (pEPR)

Due to be introduced in January 2025, mandatory recycling labelling of packaging will now not be included in the first stages of Extended Producer Responsibility for Packaging (pEPR). This is, however, a temporary position, and Defra has made it clear that mandatory labelling will be included in future amendments to the legislation. With this in mind and knowing the growing importance of sustainability among consumers, manufacturers should be thinking about their labelling requirements when it comes to recycling. - Allergen labelling

The number of global food recalls related to allergen labelling remains significant and as such, manufacturers should prepare for stricter labelling guidance to be introduced at some point in the future. In addition, the demand for healthier food and more transparency surrounding ingredients means the labelling of high in fat, salt and sugar (HFSS) foods is also likely to come under increased scrutiny.

The importance of compliance

Compliance with labelling regulations is essential if manufacturers want to maintain trust, avoid penalties, and ensure smooth distribution. Improperly labelled goods can face import/ export restrictions, resulting in disruption to supply chains – and businesses may even lose access to that market if their products consistently fail to meet the specific labelling standards of a particular region.

More importantly, in the food and pharmaceutical sectors, non-compliance can lead to health risks for consumers which can trigger recalls, damage brand trust, bring about legal action and result in significant financial penalties.

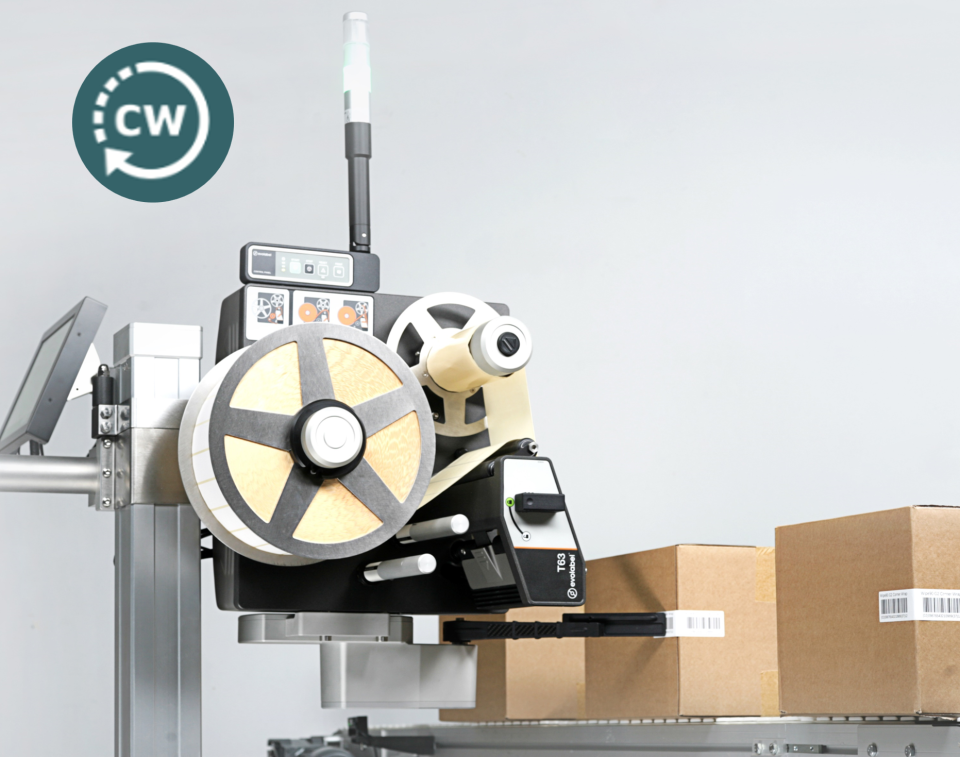

How print and apply systems help ensure compliance

Print-and-apply labelling solutions print labels on demand and automatically apply them to packaging, so placement is accurate and consistent. Because they integrate with existing workflows and connect to company databases and systems, they help to streamline the labelling process, helping businesses to stay compliant in the following ways:

Integration with regulatory databases: Print and apply solutions can also integrate with regulatory databases to access real-time updates on labelling requirements. This means businesses can adapt quickly to changes without manual intervention.

Flexible label printing: On-demand printing of labels makes it easier to accommodate frequent regulatory updates. Businesses can update information without disrupting production which is especially valuable in highly regulated industries like pharmaceuticals and food.

Track and trace capabilities: Unique product details and records of origins and distribution can be added to labels. This helps to comply with traceability requirements, vital to ensure authenticity and when dealing with recalls or other issues.

For more information on print and apply labelling and staying compliant, talk to us today.

Email Our Team

* Please complete all fields