Regular print + apply machine maintenance is essential to keeping labelling operations running efficiently. A well-maintained system delivers reliable performance, reduces downtime, and extends equipment life. This guide explains why regular maintenance is important, the benefits it brings, and how professional servicing ensures long-term reliability.

Why Print + Apply Machine Maintenance Matters

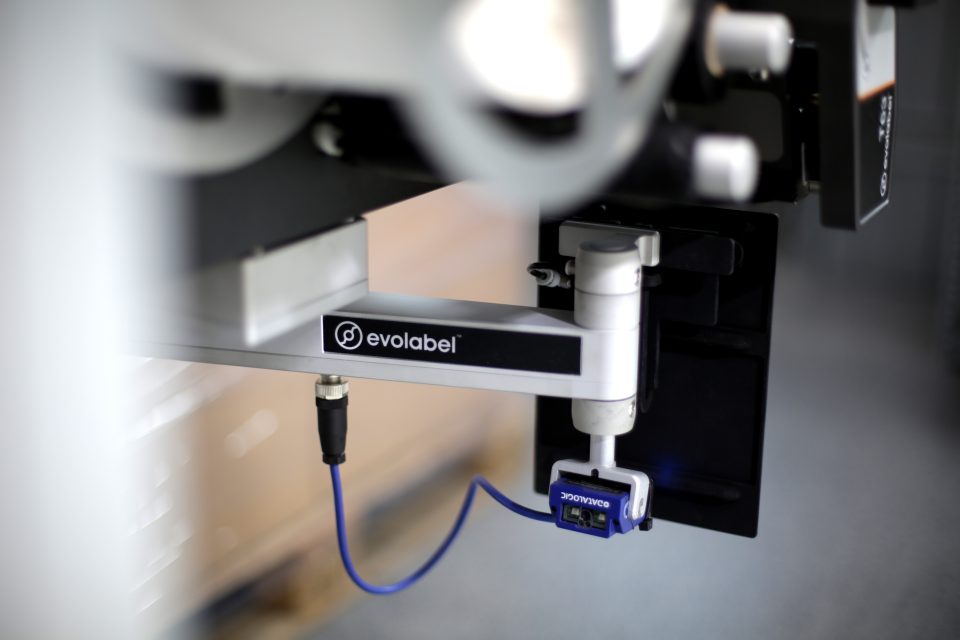

Accurate and efficient labelling is vital to the smooth running of packaging and logistics operations. Without a consistent maintenance routine, equipment failures can cause inconsistent labelling, increased wastage, and costly delays. Proactive label applicator maintenance ensures your system continues to perform at the highest standard.

Key benefits of regular maintenance include:

- Minimise downtime: Address issues before they escalate into breakdowns.

- Plan around production schedules: Carry out maintenance at convenient times, avoiding disruption during peak operations.

- Protect quality standards: Proper calibration and cleaning maintain label accuracy and print clarity, reducing errors and waste.

- Extend machine lifespan: Regular servicing increases the longevity of both print and apply systems and label applicators.

Preventative Maintenance and Servicing

While daily checks of print and apply machines are important, professional servicing provides additional protection and peace of mind. Experienced technicians can spot potential problems early, helping avoid unscheduled stoppages and costly repairs.

At Industrial Labelling Systems (ILS), we support customers with Preventative Maintenance Contracts that keep equipment in peak condition.

Our Preventative Maintenance Contracts include:

- Pre-planned service visits across the year

- Full inspections, recalibration, cleaning, and functional testing

- Replacement of worn or damaged parts before failure occurs

- Discounts on spare parts, breakdown call-outs, workshop repairs, and training during the contract term

This structured approach to print + apply machine maintenance maximises uptime, ensures compliance with quality standards, and safeguards your investment in labelling systems. It’s the best way to stay ahead of problems, keeping your systems reliable and production lines moving.

Ensure the longevity and reliability of your print and apply system. Contact ILS today to learn more about our Preventative Maintenance Contracts, professional servicing, and ongoing support packages.

Email Our Team

* Please complete all fields