High repair and maintenance costs usually mean it’s time to replace existing equipment, which is why a long-term partnership with a trusted supplier was key to Crown Packaging Europe’s decision to install new pallet labelling technology from Industrial Labelling Systems Ltd (ILS).

Crown made ILS the first port of call when it needed to modernise a pallet labelling operation at the company’s packaging facility in Carlisle, having had previous experience of the labelling specialist’s automated solutions and dependable customer support.

Introducing new pallet labelling equipment

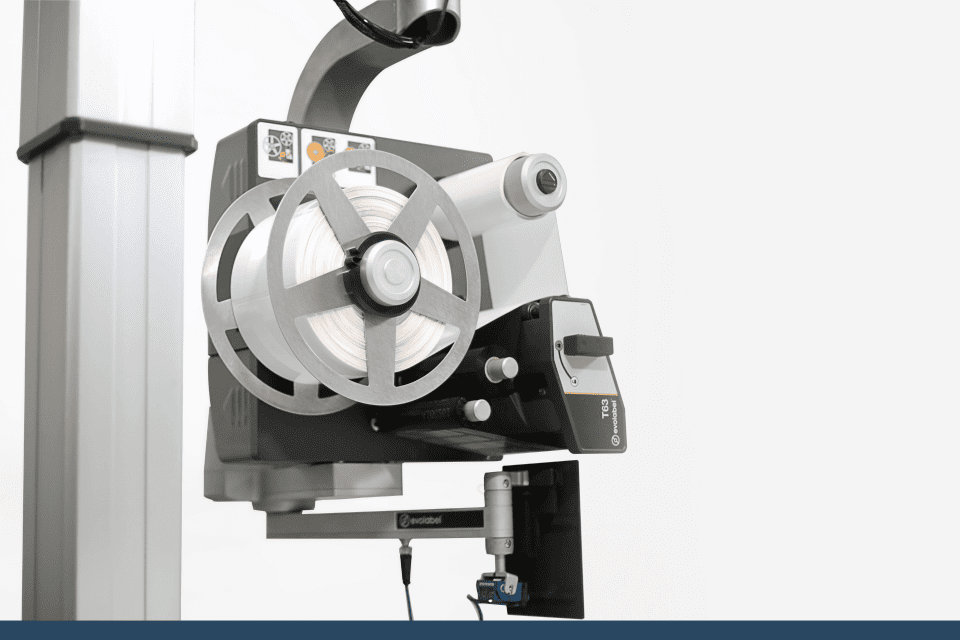

After reviewing Crown’s urgent requirements for replacing the faltering pallet labeller, ILS identified the state-of-the-art T63 FlexWipe as the perfect fit for a client that is a world leader in the manufacture of cans for the drinks, food and aerosols industries.

ILS’ highly accurate printers and applicators are renowned for operating in the most challenging conditions, offering peace of mind and the future proofing that is so essential for customers like Crown, who focus on delivering innovation to help build brands.

A brilliant solution

Crown’s EHS & Site Services Co-ordinator, said that following successful trials of the equipment and an extremely smooth installation with the support of the ILS team, Crown had a “brilliant solution” for its needs.

He added: “The FlexWipe is a great bit of kit, it’s extremely easy to operate with a good user interface. I’ve worked with ILS for several years which is the main reason why we chose the T63. They know our business so we didn’t consider any other suppliers. I would highly recommend them to anyone.”

T63 FlexWipe

Developed by Evolabel and available in the UK and Ireland from Manchester-based ILS, the T63 FlexWipe is a versatile, automated pallet labelling solution which can boost operational efficiency by performing equally well at minus 20 degrees Celsius as at normal room temperature.

Simple and straightforward to install and operate, the T63 FlexWipe’s twin-motor technology ensures totally accurate positioning of labels and a unique identity – key to multiple logistics functions such as shipments, warehousing, expiry dates and storage location, which enables companies to comply with strict barcodes regulation.

It also eliminates the need for expensive guarding and has the ability to provide single pallet labelling on up to three sides or dual pallet labelling without requiring the pallet to stop, thanks to its motorised and controlled movements and lightweight arms. The T63 FlexWipe can even handle situations where pallets are not sent down the conveyor with uniform spacing.

Crown also has a regular servicing contract with ILS that helps keep downtime to a minimum, while another advantage is that routine maintenance such as changing labels and ribbons is so easy it can be carried out by any employee, even those without previous experience.

ILS is a leading supplier to a variety of sectors, including automotive, food and beverage, construction, telecoms, nuclear, logistics, warehousing and household goods. Products offered include automatic print and apply labellers, automated pallet labelling systems, outer case & tray labellers, labels, ink and ribbon, large character inkjet marking and inline barcode inspection/validation systems.

Email Our Team

* Please complete all fields