Whatever industry you’re working in, from retail to manufacturing to logistics, there’s a high chance you rely on barcodes or other forms of labelling in some way. Whether it’s to ensure the traceability of goods, maintain food safety standards or manage your inventory, labels and the information they contain can be key to keeping things running smoothly.

It’s therefore vital that your labelling processes are accurate and efficient, and that’s why businesses are increasingly undergoing ‘labelling makeovers’ to overhaul their old or outdated equipment and methods and bring them up to date.

But how do you know when it’s time for a makeover?

New system key to improving efficiency

Crown Packaging Europe made the decision to modernise its pallet labelling operation when the existing system began to falter, pushing repair and maintenance costs higher.

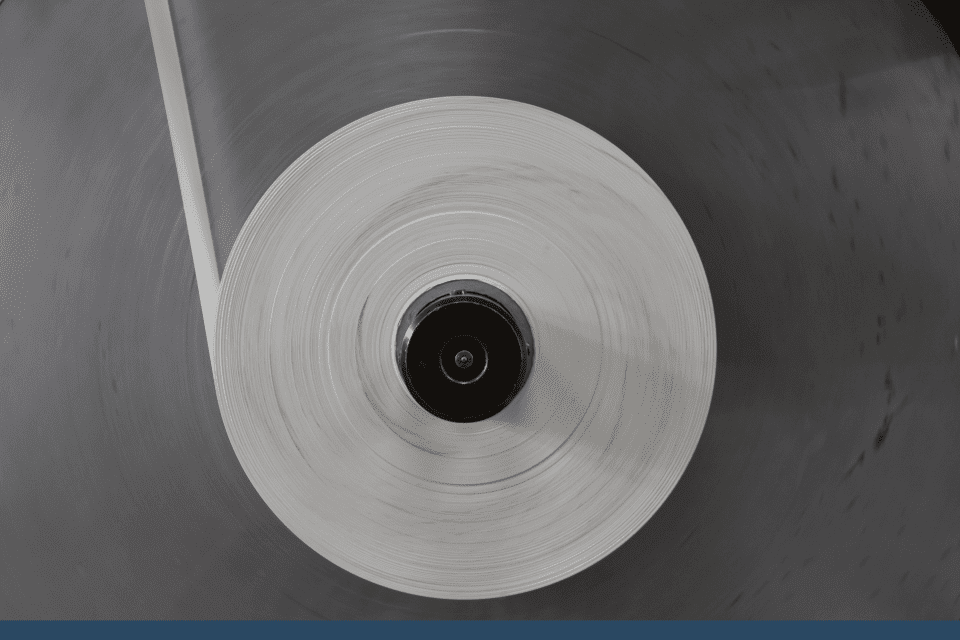

ILS identified the state-of-the-art T63 FlexWipe as the perfect fit, a versatile, automated pallet labelling solution which performs equally well at minus 20 degrees Celsius as at normal room temperature.

Simple and straightforward to install and operate, the T63 FlexWipe’s twin-motor technology ensures totally accurate positioning of labels and a unique identity – key to multiple logistics functions such as shipments, warehousing, expiry dates and storage location, which enables companies to comply with strict barcodes regulation.

Four signs you’re due a labelling makeover

If you’re wondering whether your business could benefit from a system upgrade, here are four key signs to look out for:

1. Slow and time-consuming labelling

Preparing labels by hand is an inefficient use of time; not only does it cause bottlenecks and delays, but every minute spent on it is diverting your team from tasks that could be driving growth.

If you’re still relying on manual methods, such as handwriting labels or manually entering information, it’s likely the process is extremely time consuming and inefficient. This slow speed is one of the main signs that your processes require improvement, especially if you’re looking to boost productivity or scale your output.

2. Frequent labelling errors

If you’re seeing regular errors, it might be time to rethink how you handle your labelling. Mistakes are inevitable in manual labelling processes and whether it’s a misprint, incorrect product information or a label placed on the wrong item, the inaccuracies make you look careless and can lead to wasted resources and delayed shipments.

3. Inconsistent label quality

Another factor that influences brand image and reputation is the way your labels look. They’re often the first impression that a customer has of your company and if they’re scruffy, it can detract from the quality of your product or service.

Labels that are inconsistent or hard to read can also cause confusion and lead to incorrect and missing deliveries. If this sounds familiar, it’s likely time for an upgrade.

4. Lack of visibility and traceability

Simple manual labelling systems typically don’t allow for real-time tracking, which can make it more difficult to trace products through the supply chain, manage inventory and implement recalls if needed.

In some industries, such as pharmaceuticals and food, this traceability is a vital part of compliance, so if you can’t offer it, you’re immediately at risk

How to upgrade your labelling processes

If any of the previous section sounded familiar, then there is a solution. Print and apply labelling systems are automated solutions that integrate seamlessly with your existing workflows, removing the need for manual labelling and ending the associated inefficiencies.

Print and apply systems provide:

- Increased speed and efficiency: Because labels are generated on demand, printed and applied automatically, the entire process is streamlined, removing unnecessary delays.

- Reduced errors: Data integration ensures the correct information is used for each label, and automatic printing reduces the likelihood of spelling mistakes and other human errors.

- Consistent quality: Professional, high-quality labels present the right image every time and uniform printing means your brand style is clearly identifiable.

- Enhanced visibility: By capturing real-time data, print and apply systems make tracking and compliance quick and easy.

If your current system is slow, prone to errors, or lacks real-time visibility, it may be time to consider a labelling makeover.

Learn more about our range and how we can help here.

Email Our Team

* Please complete all fields