Pallet Labelling

The latest design of Pallet labeller is safe, user friendly, extremely compact, fast and future proof for all your pallet labelling needs

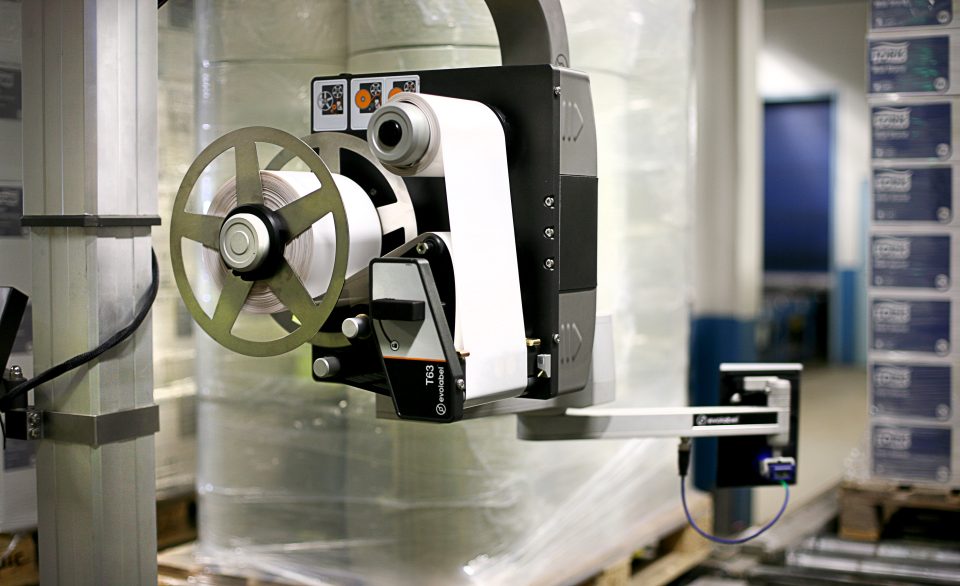

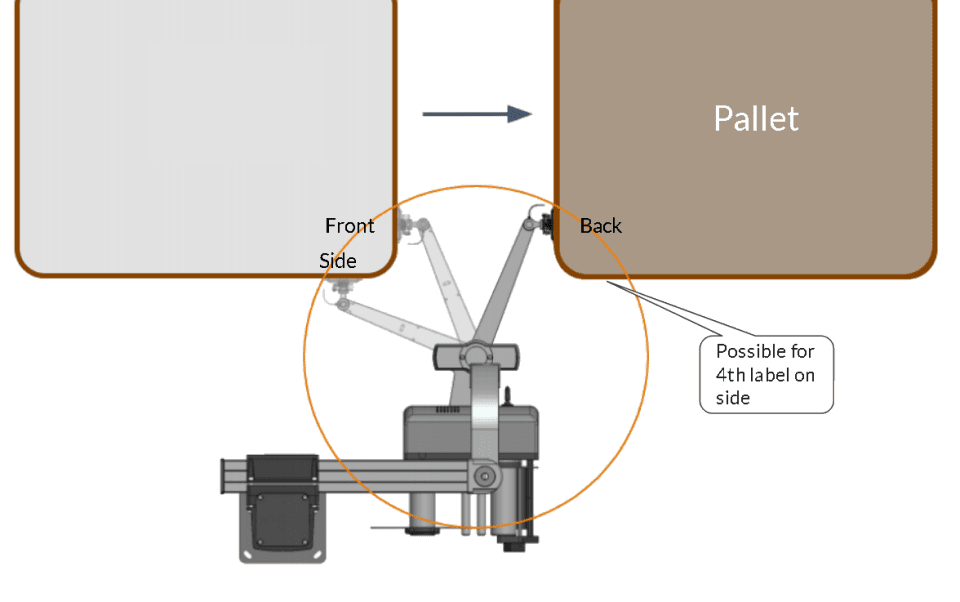

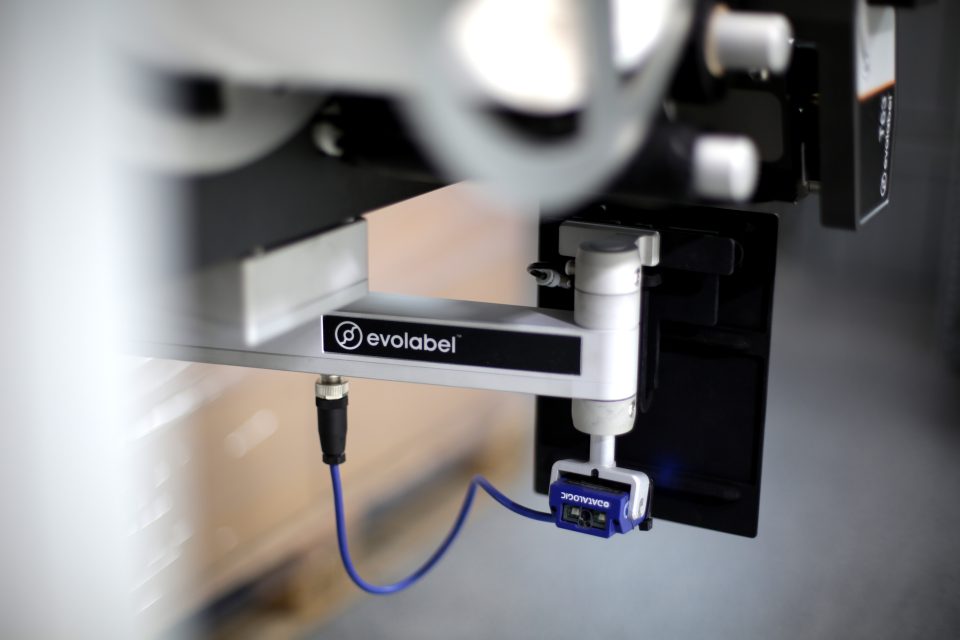

The FlexWipe is future proof due to both the compact nature of the unit and the same applicator can label all three sides. The FlexWipe Pallet Labelling System is built upon two rotating movements. The inner arm can rotate 360º and the labels can leave the printer in two directions. The outer arm can rotate 200º. A camera based scanner is located behind the applicator pad. When a validation check scan is required the arm moves away from the pallet and the outer arm turns 180º to take a picture of the label. The FlexWipe Pallet Labelling System is fully compatible with Evolabel’s existing industry standard T63 printer, using the same Evolabel standard applicator interface as with all the other applicators in the range.

Advantages of the Pallet Flex Wipe System

- Non dangerous. Operator can’t get stuck between applicator arm and pallet.

- Negates the need for expensive guarding.

- The paper roll always point towards the operator.

- Same machine configuration regardless of application (front/side/back)

- One stop for two side labelling.

- Motorized and controlled movements both horizontally and vertically.

- Lightweight arms make the applicator fast but hazard free.

- The applicator can label three sides without having the pallet to stop if check scanning is not required.

- Built in Validation check scan

- Operational down to -28c

A Giant Leap For Pallet Labelling

Check the innovations:

- Unparalleled Safety

- Safe Automated Height Adjustment

- Flexible, Fast and Compact

- Labelling on Rough or Cold Surfaces

- Operation Down to -28ºC with the Multi side, FlexWipe™

- Automatic Portrait or Landscape Mode

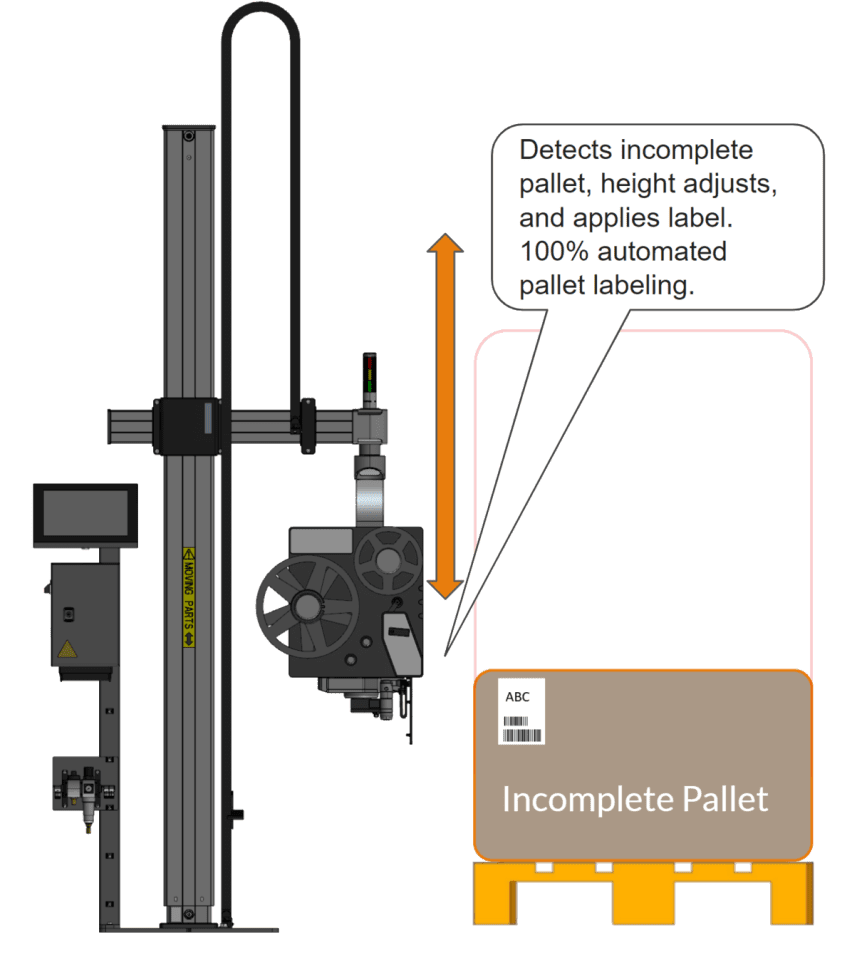

- Incomplete Pallet Detection

- Dependable Code Validation

Multi Side, FlexWipe™

- Feature-rich front, side and back labelling

- T63 G2 Thermal Transfer Printer with touch screen

- FlexWipe™ applicator

- A5 / 6″x8″ applicator pad with pressure brushes

- Status beacon lights (red=error, yellow=warning, green=ready)

- Fixed stand, up to 4 m or Automated height adjust Motorized Stand XL labelling from 740 to 2140 mm (top of label)

- Options:

Incomplete-pallet detection sensor

Automatic portrait or landscape mode

Barcode validation

Other applicator pad formats available

Single Side Labelling

Economical one-side labelling

- 3 Thermal Transfer Printer with touch screen

- eTamp Applicator stroke depth of 650 mm

- A6 / 4″x6″ applicator pad

- Status beacon lights (red=error, yellow=warning, green=ready)

- Fixed stand, up to 2 m or automated height adjust Motorized Stand XL, labelling from 740 to 2140 mm (top of label)

Options

- A5 / 6″x8″version

- Other applicator pad formats available

Cold Storage Pallet Labelling

The ILS Flexwipe Pallet Labelling system is a proven sub zero environment system that enhances any cold storage facility without slowing down the movement of pallets or increasing the risk of operator error / injury.

Operation Down to -28ºC with the Multi side, FlexWipe™

The robust design of all standard Evolabel printers delivers exceptional performance even in frozen food settings down to -28ºC. The FlexWipe™ applicator also functions without stop in these cold conditions. No need for additional heaters or special cabinets to do cold storage labelling.

Key Items for Cold Storage Labelling

- Direct Thermal Labelling – No Ribbon

- Less Moving Parts

- Small footprint

- No Additional enclosure

- No heater for additional enclosure

- Versatile wipe system for irregular pallets

- Portrait and Landscape options

Unparalleled Safety

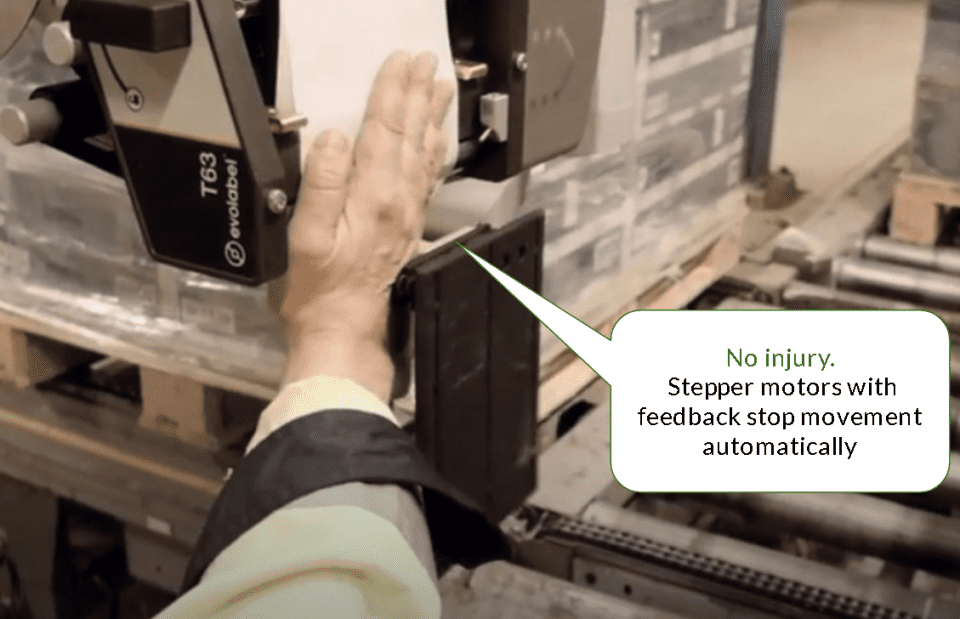

Eliminates hand pinch points

The units automatically stop when a hand is front of the applicator or in other possible pinch points. The Multi Side, Flexwipe™ continuously monitors applicator movement with pulse encoders inside the controlling stepper motor. If movement is unusual, the unit stops automatically. No cumbersome coverings required allowing easy access when changing label rolls the ink rolls.

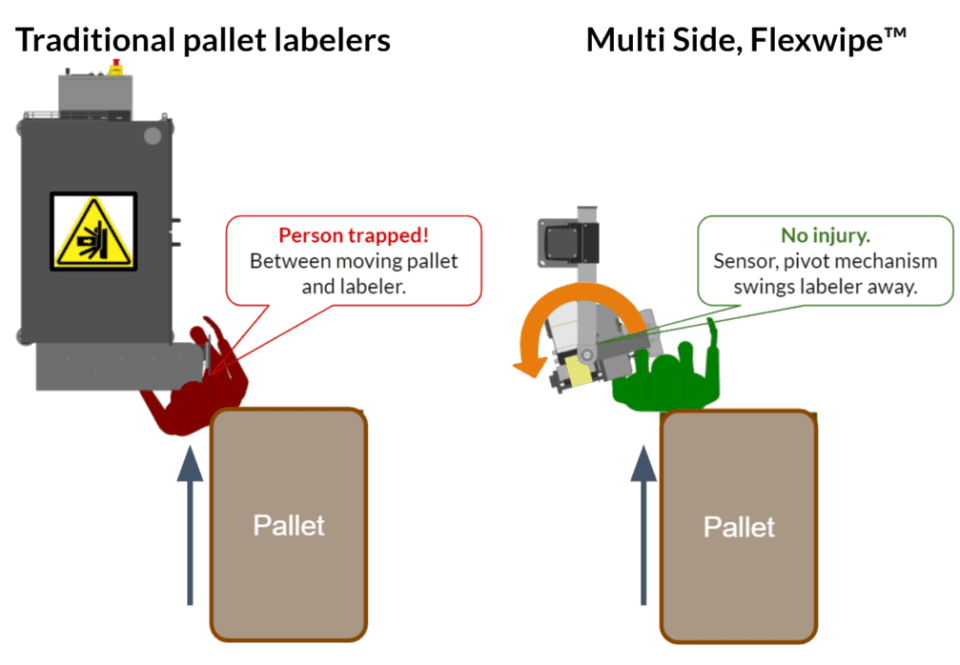

Handles whole body pinch points

Injuries happen when a person gets trapped between a heavy moving pallet and a stationary labeller or rigid label applicator. If a person does get between the labeller and pallet, the Multi Side, FlexWipe™ arm retracts and and the pivot-able mount allows the whole unit to swing out of harms way.

Safe Automated Height Adjustment

If up or down movement is slightly hindered, the Motorized Stand XL immediately stops and blasts a warning. As the system moves up and down, the labeller has almost no downward force. This is due to pressure-controlled pneumatics and the stepper-motor controlled, rotating ball screw mechanism. The motor’s pulse encoder with a laser height-sensor constantly monitors and control the movement (patents pending). A safety brake ensures stopping the system if power or air is disconnected.

Flexible, Fast and Compact

The patented design of the Multi Side, FlexWipe™ applicator turns 360º in any direction. The outer movement is controlled independently from the inner movement providing labelling in 4 positions. This flexible movement is fast, due to the design of 2 rotational movements/joints driven by stepper motors. The whole unit, including stand, takes up less than 1 ㎡ of floor space.

Labelling on Rough or Cold Surfaces

Pallet surfaces are commonly uneven, rough or cold. After the label is tamped on the pallet, the FlexWipe™ applicator uses brushes to “wipe” carefully over the label, pressing the label into the surface. Labels stick even under the poorest adherence conditions.

Automatic Portrait or Landscape Mode

Choose the format during label design and let the Multi Side, FlexWipe™ do the rest. No need to change label apply mechanisms as required by most other labellers. In the FlexWipe™, format changes does not slow the labelling speed; the dynamics of the pressurized air -motor controlled, rotational joint, holding the applicator pad keeps the labelling process moving.

Incomplete Pallet Detection

The Multiside, FlexWipe™ automatically labels the infamous last, incomplete pallet from a production run. Finally, 100% automation is achieved in pallet labelling! Monitoring the pallets surface with a special sensor, the FlexWipe™ moves down to a suitable labelling surface and only then, applies the label.

Dependable Code Validation

The ingenious integration of the code-reading camera combined with the controlled movement of the applicator arm, ensures that 1 or 2D codes are read correctly. This eliminates operational downtime from false negative readings. Red and green lights tell operators the result of the read.

Streamline your pallet labelling with our solutions, fully compliant with global GS1 and SSCC standards.

Enhance item handling and tracking efficiency with our reliable barcode labels. Learn more about SSCC here.

Email Our Team

* Please complete all fields